3D Printing Cerambot Eazao Might Fulfill Your Pot Habit

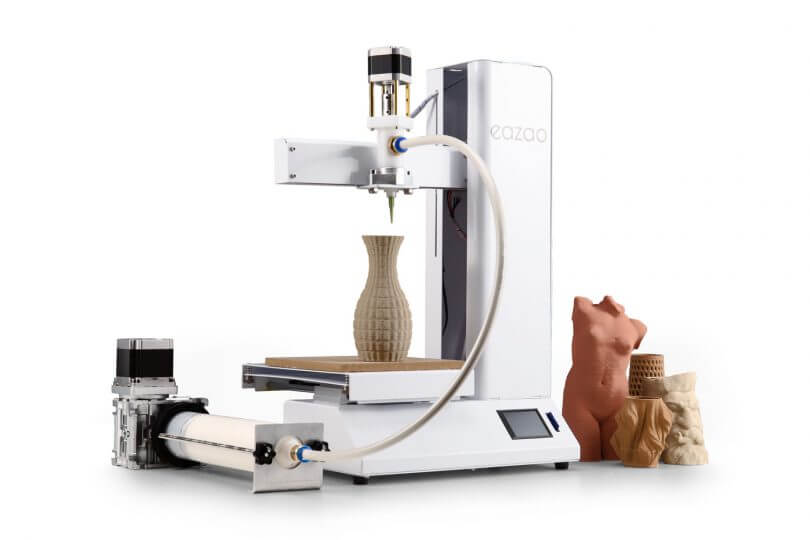

Pottery meets tech in the Cerambot Eazao, a compact 3D printer that turns clay into stunning vessels. Perfect for hobbyists and designers, it makes crafting unique ceramics faster, cleaner, and more accessible.

In certain circles ceramics have become the hobby de rigueur (some even call it a popular “pot habit“, if you may). While working with clay in itself is accessible, access to a large electric kiln to finalize the glaze is not. The Cerambot Eazao suggests a promising workaround, an additive 3D printer using clay and porcelain as its printing medium that allows the aid of a common household appliance to set and finalize the glaze.

Jony Liu, CEO of Cerambot, says the Eazao is designed to prioritize simplicity, with a fully-assembled design that doesn’t require a compressor, nor a traditional large size kiln for sintering/glazing. After designing a model in 3D modeling software, the Eazao begins its work using a syringe extruder. The performance of Eazao’s predecessor, the Cerambot, offers reference of what to expect.

The resulting clay piece can be further sanded/finished by hand then placed into a microwave using Cerambot’s own special kiln; 35 minutes at full power as the interior reaches temperatures required to harden the material to a finished and usable state, sort of like a Play-Doh meets an Easy Bake Oven for adults.

The microwave process does limit the printed designs to be fairly small proportions – think small drinking cups – but larger objects are possible minus the microwave (or with access to a traditional kiln).

Eazao is set to pre-launch with the offering of a limited early supporter price of $399 before doubling the price later for its official retail release, with plans to make early launch announcements via the Cerambot Eazao website.